Buffering volatility and disruption with best practices

A ten-minute takeaway to ensure your demand management and forecasting circumvents failure.

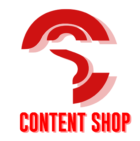

Demand management and forecasting calls for disruptions and buffering operations with optimized tools and techniques. This is a ready primer for enterprises who maintain systems in place but are forced to switch to ‘Plan B or C’ due to unavoidable circumstances. Implementing the best practices for meeting the capacity of customer requests gives a significant competitive edge.

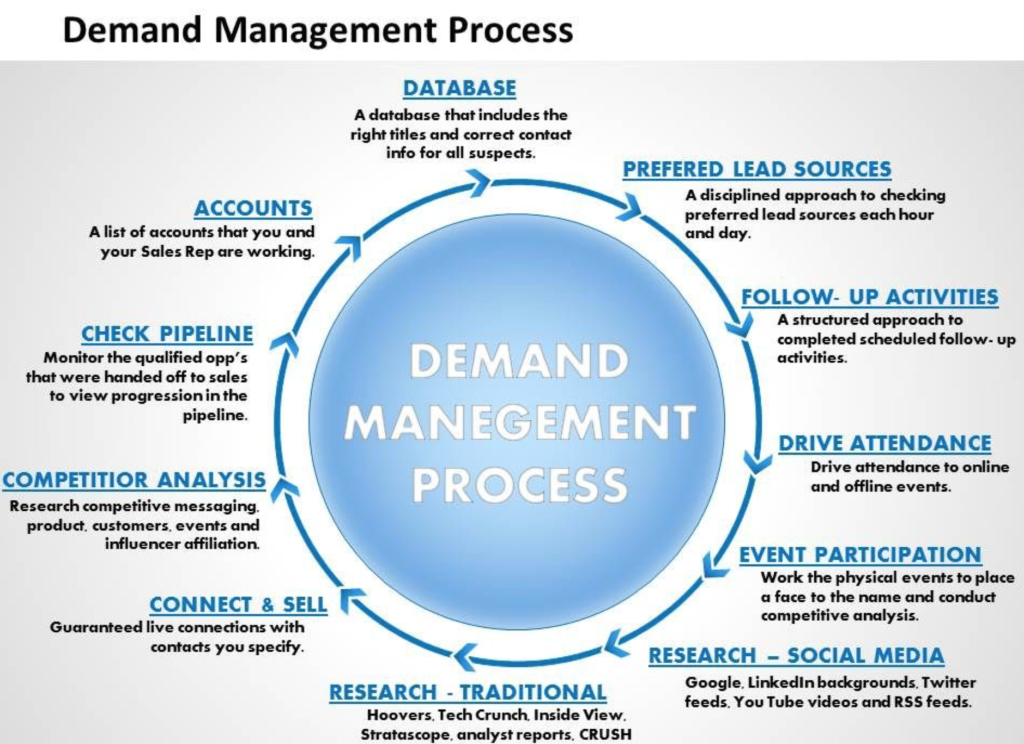

Demand Planning or Demand forecasting?

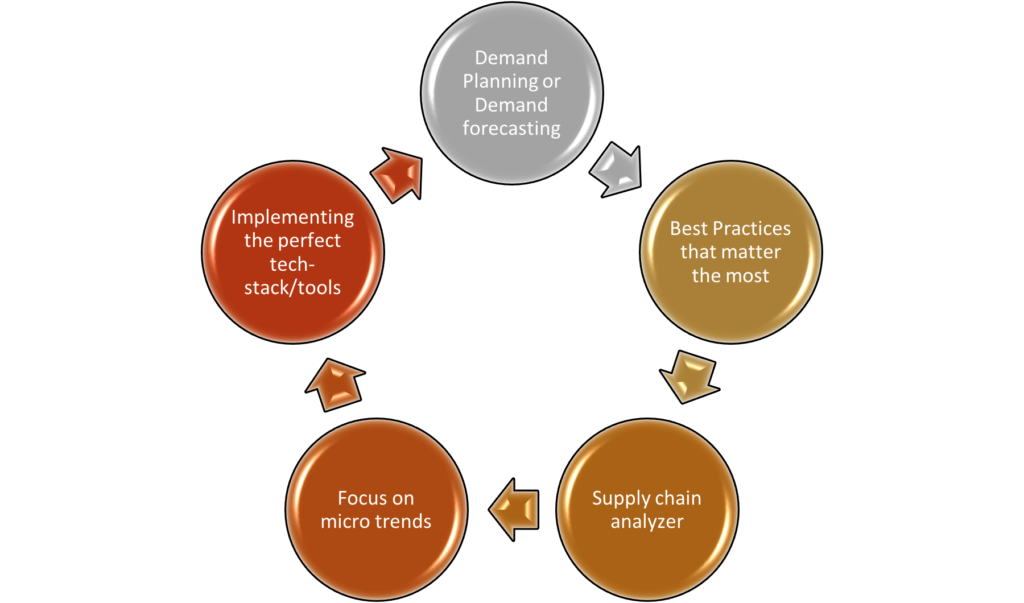

Your most reliable customer is prone to switching over to the next vendor if there is a gap between the demand and capacity to deliver on time. Unless a Plan B ready, revenue generation will be hit sooner or later. Knowing that there is no 100% forecast or prediction to fall back on, a few effective practices break the adverse impact of volatility. Management systems within the organization depend on demand planning and at some stage forecasting methods to reduce variables or errors. If you stick to the following three realistic expectations your capability to deliver will never be questioned.

These three points will enable the manager to forecast the necessity for product supply. It attaches value to demand planning and predicts ‘consumer rush’ for specific items in different seasons.

Best practices for demand management

- Forecast value metrics – evaluate all different components for implementation and eliminations of items.

- Gathering insights from all departments, customers and the marketing teams.

- Improving accountability for better forecasting by taking note of PoS customer data.

- Detecting gaps and covering supply chains.

- Collecting the downstream data affecting revenues.

- Giving values to upstream data and immediate stipulations.

Many businesses collect considerable revenues from 20% of their quality products. Keeping this in mind making classifications for forecasting is important. A demand planning software has provisions for classifications and valued charts to keep the top 20% items always in the inventory. This is why key performance metrics provide an edge despite market variables.

Avoid supply chain analysis paralysis

Supply chain modules are crucial to business grows. Planning ensures there are no roadblocks. Today the best automated solutions target planners who wish to avoid the analysis paralysis. Software with additional features allows better movement of the stock. Combined with other apps, the system works with accuracy especially when the demand is high. This could be your big ticket to delivering products to consumer faster than others. You can enhance several operations via:

Sales and operations

Risk Analysis

Demand forecasting

Supply chain integration

Project Management

Focus on micro trends

You can rely on micro-trends only if your knowledge about the market is on the finger tips. While planning most managers pay attention to the big picture. As an effective strategy why not shift the gaze towards mirco trends? You could discover data points to bridge the gaps and make demand management closer to accurate levels. Considering that customers and supply chains are now global, it is critical to tap them with better forecasting tools and techniques. There are some mistakes that demand managers make and can be eliminated by adopting the right market trends. Take a step back. Get a rear view image of the demand for your best selling products. Implementing a customized tech–stack clears the focus. It will encourage you to respond to market requirements with a better turnaround time.

Implementing the perfect tech-stack

The use of AI, ML and robotics in large warehouses remain a reality. Even though robots and chatbots are not likely to take over from humans, demand managers still have a serious job to perform. They need to be prepared to switch to best practices with the right tech-stack and real time analytics before making promises. The workflow of the backlog and new stock need better planning. If you are capable of improving this funnel with flexibility, meeting organizational goals will not be dependent on a Plan B.

Are you prepared to increase your productivity levels with the above best practices for demand management?